Gear Up Your Fulfillment Warehouse for the Holiday Rush

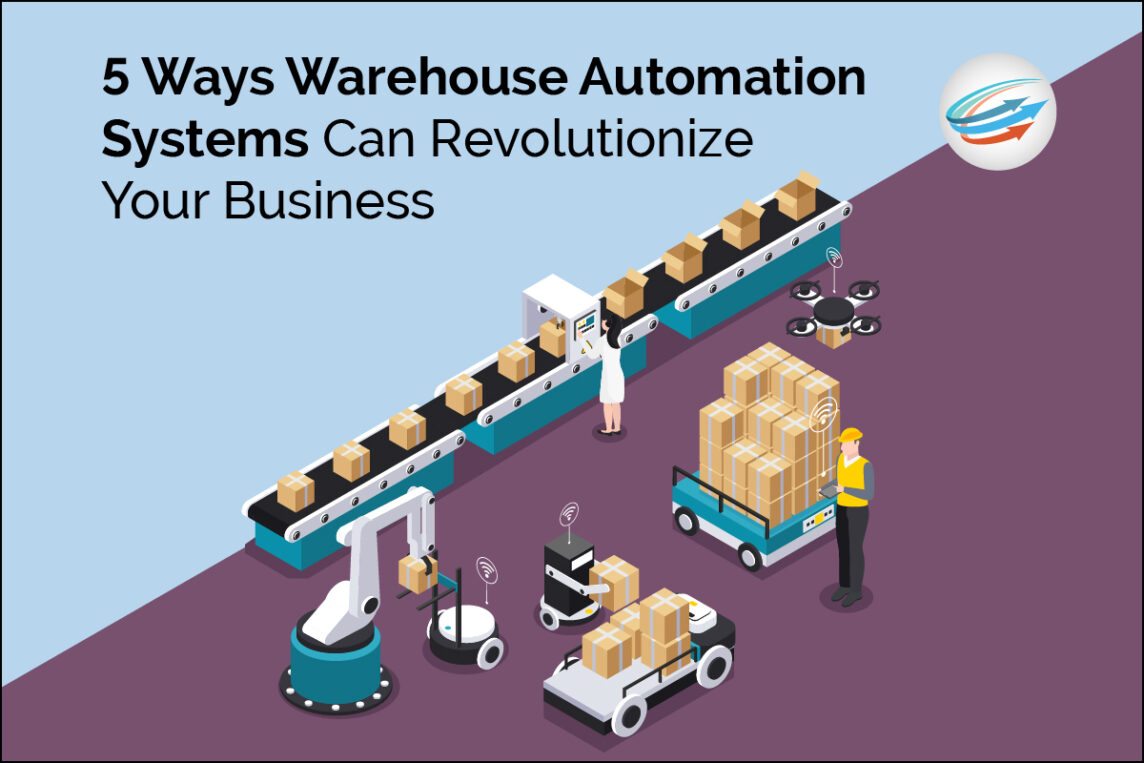

5 Ways Warehouse Automation Systems Can Revolutionize Your Business

The Future of Warehousing: Predictions and Trends to Watch

Keys to Improve Your Warehouse Management

Warehouse managers have the difficult task of keeping track of all the materials in a warehouse, including where products are currently located and where they should be. You would think the advancement of software has made this job somewhat easier—and it has to some degree—but software advancement has also led to added responsibility. What Is a Warehouse Management System? Software that is able to process the day-to-day operations of a warehouse is considered a warehouse management system. Previously, these systems weren’t able to do much more than locate products within a warehouse—but warehouse management systems can now track a package for...

Warehouse managers have the difficult task of keeping track of all the materials in a warehouse, including where products are currently located and where they should be. You would think the advancement of software has made this job somewhat easier—and it has to some degree—but software advancement has also led to added responsibility. What Is a Warehouse Management System? Software that is able to process the day-to-day operations of a warehouse is considered a warehouse management system. Previously, these systems weren’t able to do much more than locate products within a warehouse—but warehouse management systems can now track a package for...What Are the Different Types of Order Picking Methods in the Warehouse?

Warehouse order picking methods are an important aspect within any warehouse. Compared to shipping, storage, and receiving stages, order picking forms as much as 55% of operation costs in a distribution center. It also has a direct impact on how satisfied your customers are. If your picking methods in the warehouse are quick and accurate, your business will succeed. Here’s what you need to know about order picking and how to implement the key warehouse picking best practices. What Is Order Picking? Order picking is the process of selecting items from a warehouse inventory, to satisfy several independent customer orders....

Warehouse order picking methods are an important aspect within any warehouse. Compared to shipping, storage, and receiving stages, order picking forms as much as 55% of operation costs in a distribution center. It also has a direct impact on how satisfied your customers are. If your picking methods in the warehouse are quick and accurate, your business will succeed. Here’s what you need to know about order picking and how to implement the key warehouse picking best practices. What Is Order Picking? Order picking is the process of selecting items from a warehouse inventory, to satisfy several independent customer orders....Everything You Need to Know about Warehouse Robotics

Top 10 Tips for Small Business Warehousing

Disadvantages of Public Warehousing

When looking for third-party warehousing solutions, your options will come in one of two types: contract or public warehousing. On the surface, the two can appear interchangeable and it can be hard to tell what public warehousing is when compared to contract options. Each is run by a third-party operation that offers storage space, better shipping rates, seasonable scalability, value added services, and so on. But there are several public warehousing disadvantages you ought to be aware of. But before we get to the pros and cons of a public warehouse, let’s highlight the differences between public and contract warehousing....

Hidden Costs of In-House Warehousing

[caption id="attachment_5990" align="alignleft" width="481"] iStock.com/Smederevac[/caption] There are many reasons why growing companies switch from managing their warehousing in-house to hiring a third-party fulfillment company. There are many hidden costs and challenges when you manage your fulfillment and warehousing in-house, especially if you are a startup company. Although using a fulfillment partner may seem more expensive up front, you will ultimately save more money in the long run as your business grows. Here are some of the hidden costs of in-house warehousing, so that you can weigh your options and save on costs with a fulfillment partner. (more…)

How to Overcome These Common Challenges of Having Multiple Warehouses

[caption id="attachment_5975" align="alignleft" width="426"] iStock.com/petinovs[/caption] Adding extra warehouses to your business provides many benefits such as reducing shipping costs, increasing storage capacity, and having warehouses for specific purposes to simplify warehouse management. However, the more warehouses you have, the more challenges you may have to deal with. Here are some of the most common challenges with managing multiple warehouses and how you can manage multiple warehouses effectively to overcome these challenges. (more…)