Avoid These 8 Common Warehousing Mistakes for Optimal Efficiency

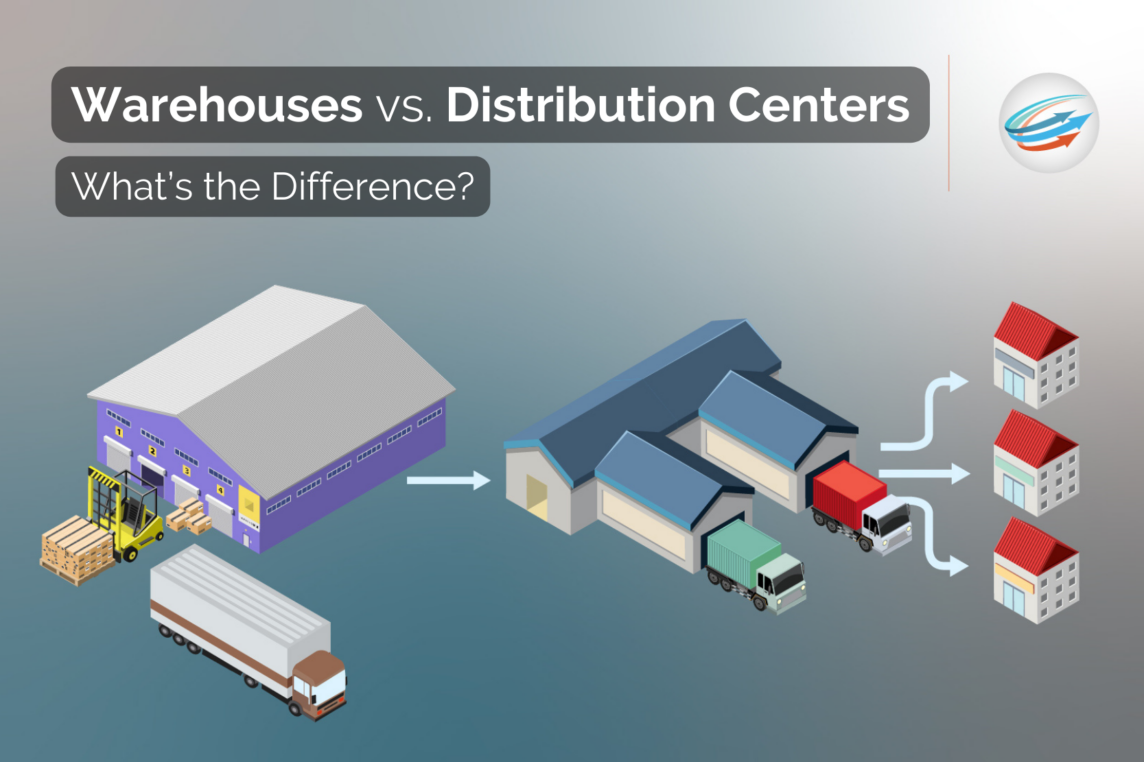

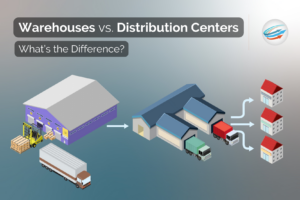

Warehouses vs. Distribution Centers: What’s the Difference?

How Packaging Helps in Successful Warehouse Management

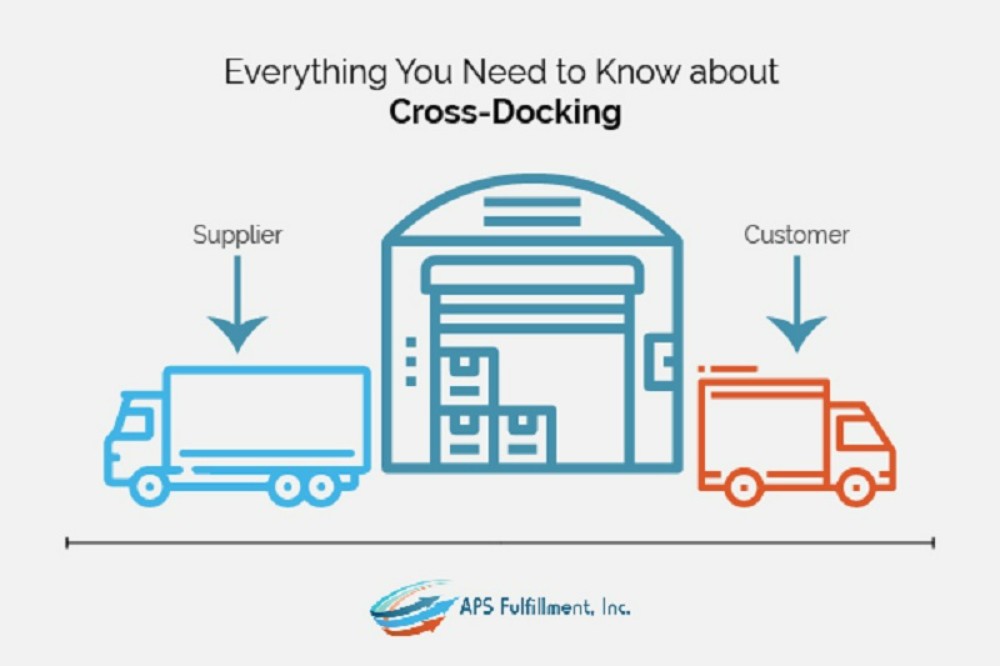

Everything You Need to Know about Cross-Docking

Warehouse Audit Checklist and Best Practices

Busy warehouse managers and business owners have little time to waste. They want their team to be on top of everything they are responsible for, so their business runs efficiently. Part of efficiently running and managing a warehouse space is to regularly run a warehouse audit. Performing an audit of each process in your operations can be a daunting task. Instead of taking shortcuts that lead to errors, there are a few warehouse audit best practices that you should know. Check out this warehouse audit checklist to help you determine which areas of your business you should audit. (more…)

How to Optimize Your Warehouse Replenishment

[caption id="attachment_6015" align="alignleft" width="300"] iStock.com/Wavebreakmedia[/caption] With the increasing pressure to deliver faster order fulfillment, it’s more important than ever for companies to streamline, improve, and reassess their existing warehouse operations and practices. Thanks to recent advancements in picking technology, companies are beginning to see improvements in their warehouses; however, one area that continues to be overlooked is replenishment. Here’s what you need to know about the importance of stock replenishment, plus we provide some helpful warehouse replenishment best practices to help you streamline your inventory management in your warehouse. (more…)

How to Manage Inventory when You Have Multiple Warehouses

[caption id="attachment_6009" align="alignleft" width="300"] iStock.com/Drazen Zigic[/caption] The warehouse is the core of inventory management where all goods are received, sent to production, and shipped out and delivered to customers. All these aspects must be streamlined and in perfect synchronization to ensure that your customers get their orders on time. As straight forward as it may seem, inventory management is not an easy task, especially when it comes to inventory management for multiple warehouse. The key to successfully managing multiple warehouses is to get a good understanding of the challenges they present and develop strategies for how to overcome them. Here...

How to Overcome These Common Challenges of Having Multiple Warehouses

[caption id="attachment_5975" align="alignleft" width="426"] iStock.com/petinovs[/caption] Adding extra warehouses to your business provides many benefits such as reducing shipping costs, increasing storage capacity, and having warehouses for specific purposes to simplify warehouse management. However, the more warehouses you have, the more challenges you may have to deal with. Here are some of the most common challenges with managing multiple warehouses and how you can manage multiple warehouses effectively to overcome these challenges. (more…)

Everything You Need to Know about On-Demand Warehousing and Fulfillment

[caption id="attachment_5867" align="alignleft" width="498"] iStock.com/StockRocket[/caption] The warehousing and fulfillment industry has never been more popular. Thanks to the exponential growth of e-commerce sales, there is more interest and opportunity in fulfillment services than ever before. But the growth of e-commerce fulfillment is more than an increasing interest—the industry has been taken to new heights because of a new method of doing business known as on-demand warehousing and fulfillment. Over the last few years, on-demand warehousing has been one of the major goals of online retailers to achieve success and get ahead of their competitors. What is on-demand warehousing and fulfillment?...

What Is the Difference between Inventory Management and Warehouse Management?

The terms “inventory management” and “warehouse management” are sometimes mistakenly used interchangeably as they both deal with operations and products within companies in the manufacturing and distribution industry. Despite their few similarities, there are many notable differences between warehouse and inventory management systems. Warehouse managers and business owners should be aware and understand the differences between the two terms because the type of management system used to track the inventory depends on certain factors that can boost or hold back your company’s profitability and efficiency. Keep on reading to learn what each term means and what features make them different...