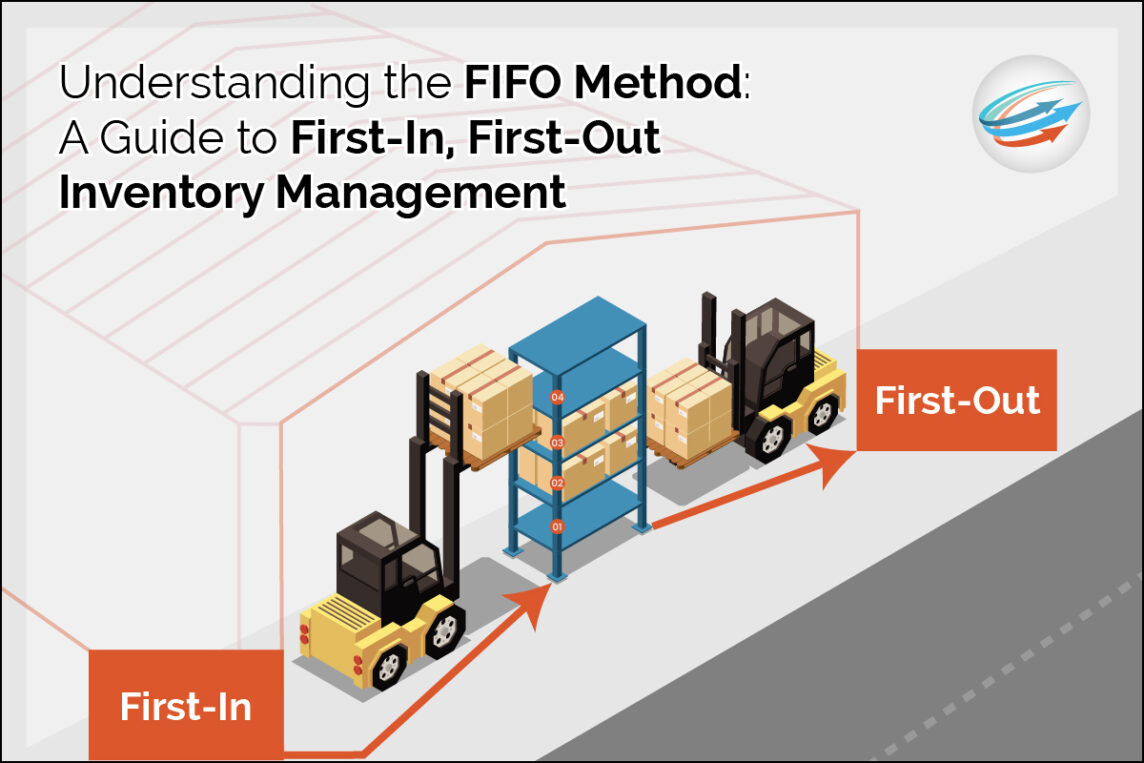

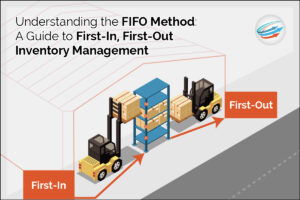

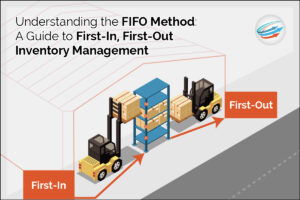

Understanding the FIFO Method: A Guide to First-In, First-Out Inventory Management

Understanding Just-in-Case Inventory for E-Commerce Success

How to Manage Seasonal Demand in E-Commerce

What Is a Perpetual Inventory System and How Does It Work?

The Hidden Cost of Dead Stock and Its Impact on Your Business

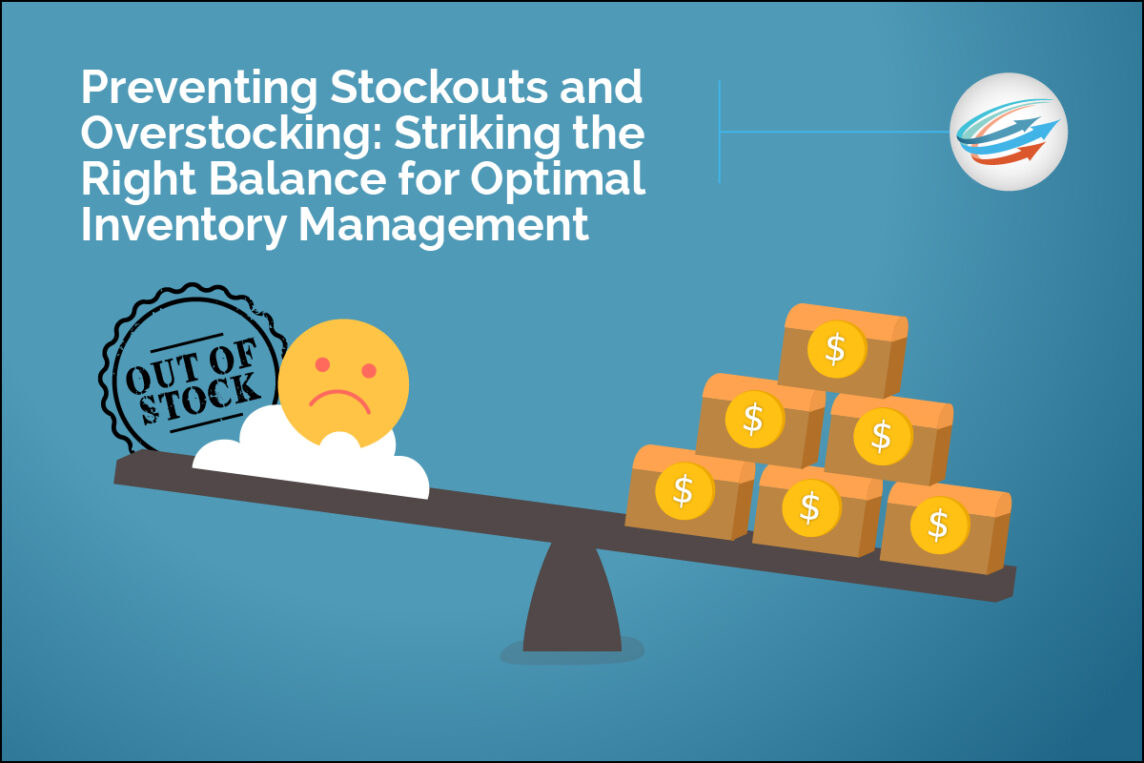

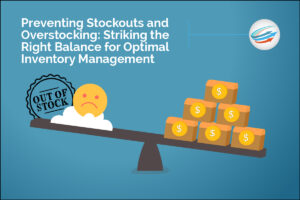

Preventing Stockouts and Overstocking: Striking the Right Balance for Optimal Inventory Management

Everything You Need to Know About Minimum Order Quantity (MOQ)

What Is a Physical Inventory Count and Why Is It Important?

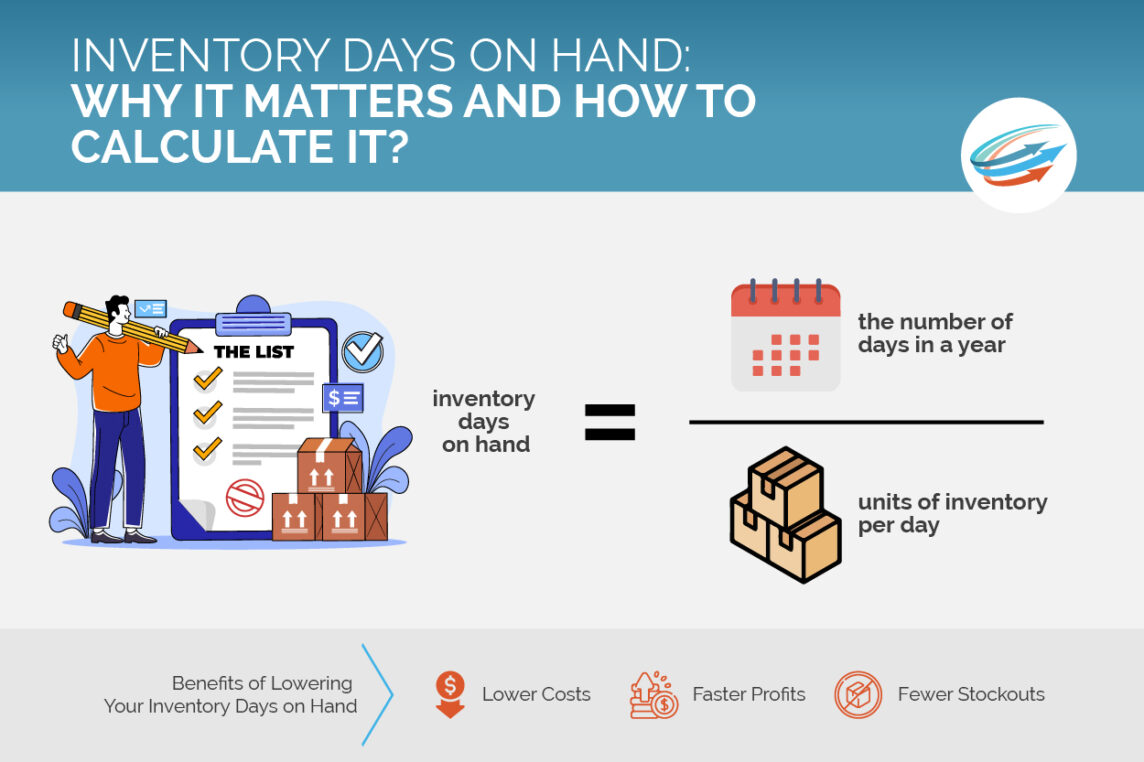

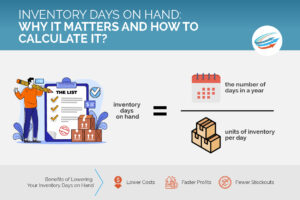

Inventory Days on Hand: Why It Matters and How to Calculate It?

Tips to Improve Your Inventory Management in 2022