If you are running a business, then you know that logistics is key. The more efficiently you can move your products from point A to point B, the more successful your business will be. That’s where cross-docking comes in.

In this post, we will discuss what cross-docking is, how it works, and some of the benefits of using this solution. We’ll also give you some tips on how to choose the right cross-docking solution for your business.

What Is Cross-Docking?

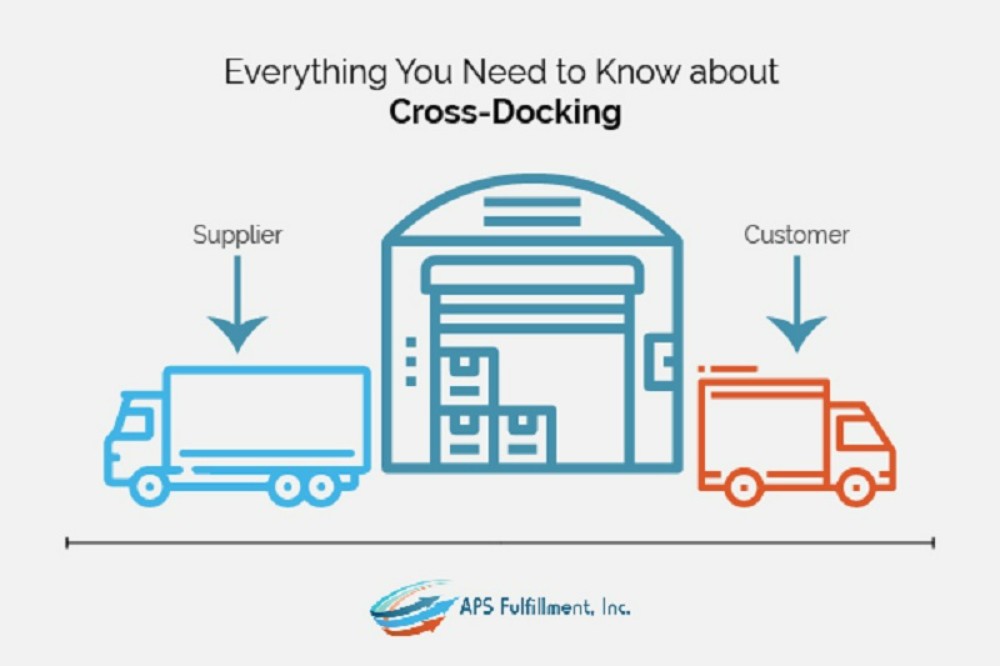

Cross-docking is a type of logistics and supply chain management in which goods are received from one truck and then loaded onto another truck headed in the same direction. This helps to reduce the amount of time that the goods spend in transit, as well as the amount of handling required.

Cross-docking can be used for a variety of different products, including food, beverages, and retail items. In many cases, cross-docking is used in conjunction with just-in-time inventory management, as it can help to ensure that products are shipped out as soon as they are received.

Types of Cross-Docking

There are several different types of cross-docking, each of which serves a specific purpose in the supply chain.

Distributor Cross-Docking

Distributor cross-docking is when a distributor receives products from suppliers and loads them onto trucks according to retailer orders. This type of cross-docking requires real-time communication between the distributor and retailer so that the correct products are always loaded onto the right truck heading to the right store.

Manufacturer Cross-Docking

Manufacturing cross-docking occurs when raw materials are delivered to a factory and then moved directly to the assembly line without being stored. This type of cross-docking eliminates the need for a finished goods warehouse and reduces material handling costs.

Retail Cross-Docking

Retail cross-docking occurs when products are delivered from distribution centers directly to stores without being stored at the retail location. This system helps retailers reduce inventory levels and stock-outs because they only keep enough products on hand to meet customer demand.

Transportation Cross-Docking

Transportation cross-docking is used by shippers to consolidate loads from multiple origins into a single destination. For example, if a trucking company has multiple loads going to the same city, they may consolidate those loads into one truck instead of sending multiple trucks. This type of cross-docking reduces transportation costs by reducing empty miles driven.

Opportunistic Cross-Docking

Opportunistic cross-docking is when companies take advantage of unexpected events to gain efficiencies in their supply chain. For example, if a company has an order for 100 widgets but receives 1,000 widgets from their supplier, they may decide to use opportunistic cross-docking to ship 500 widgets directly to their customer without storing them in their warehouse first. This allows the company to avoid paying storage costs for the widgets and reduces lead time since the widgets do not have to be picked and packed before they are shipped.

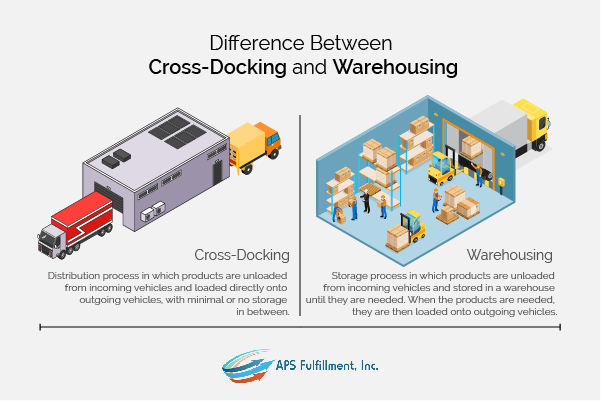

Difference Between Cross-Docking and Warehousing

Cross-docking and warehousing are two terms that are often used interchangeably. However, they actually refer to two different types of operations.

Cross-docking is a type of distribution process in which products are unloaded from incoming vehicles and loaded directly onto outgoing vehicles, with minimal or no storage in between.

In contrast, warehousing is a type of storage process in which products are unloaded from incoming vehicles and stored in a warehouse until they are needed. When the products are needed, they are then loaded onto outgoing vehicles.

Because cross-docking involves little or no storage, it is typically faster and more efficient than warehousing. However, it is only possible when there is a continuous flow of incoming and outgoing traffic. If the flow of traffic is interrupted, it can cause delays and disruptions in the cross-docking process.

Also read: Cross Docking vs. Drop Shipping: What Is the Difference?

Who Can Benefit from Cross-Docking?

Cross-docking can be beneficial for a variety of businesses because it helps to reduce transportation costs and decreases the amount of time that products spend in storage.

Additionally, cross-docking can help to improve customer satisfaction by ensuring that orders are filled more quickly and efficiently. As a result, businesses that rely heavily on shipments and deliveries can benefit greatly from implementing a cross-docking system.

Choose APS Fulfillment, Inc. to Improve Your Supply Chain

At APS Fulfillment, Inc., we offer full-service e-commerce fulfillment out of Miami that includes state-of-the-art warehouse management software (WMS) and we make inventory management and goods tracking easy. We’ll also support your business and automate the warehousing, prepping, shipping, picking, and packing of your orders!

Get in touch with us and one of our consultants will tailor a fulfillment plan designed to grow your business. Book a consultation by calling (954) 582-7450 or email [email protected].